Product Center

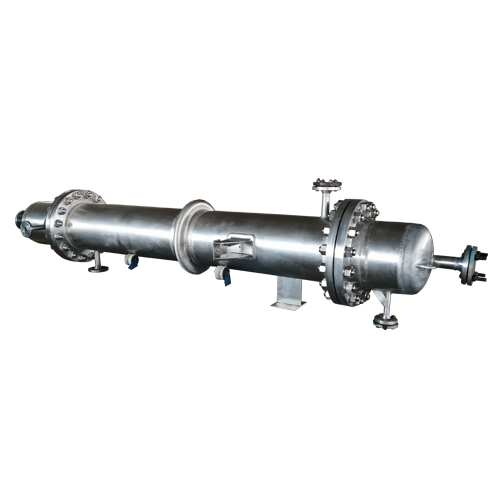

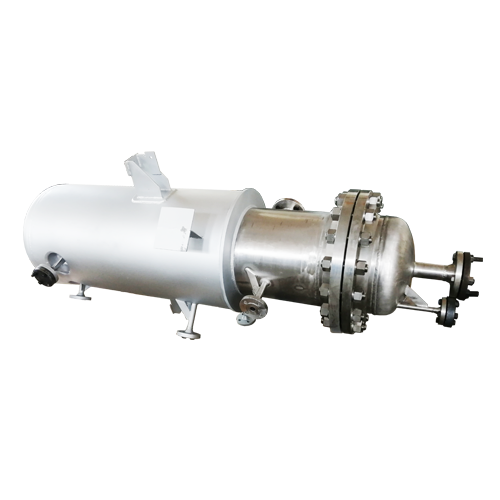

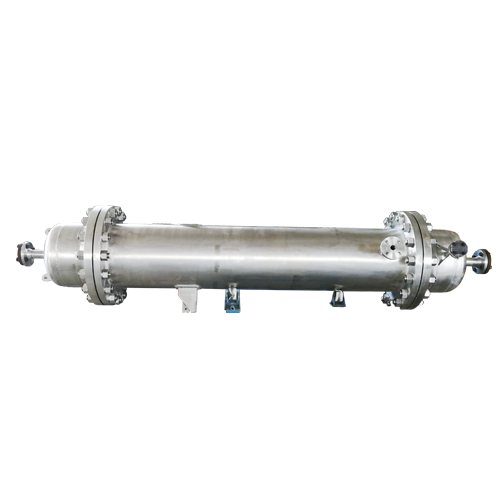

Your Current Location:Home > Product CenterThe tubes of the tube-and-tube heat exchanger can be ordinary carbon steel tubes, stainless steel tubes, aluminum tubes or copper tubes. The heat exchanger is exposed to water and organic impurities for a long time during the working process, and the tube is corroded seriously. The use of stainless steel tube can effectively prevent corrosion, the tube wall is not easy to scale, easy to clean, the heat transfer coefficient is higher, and the extension of the service life also makes up for the disadvantage of higher price. For condensers of the same area, the difference in tube material and cooling medium flow rate has a significant impact on the heat transfer coefficient.

The heat exchanger is a device that transfers part of the heat of the hot fluid to the cold fluid, also known as the heat exchanger. Heat exchanger occupies an important position in chemical, petroleum, power, food and many other industrial productions. In chemical production, heat exchangers can be used as heaters, coolers, condensers, evaporators and reboilers, etc., and are widely used .

In a floating head heat exchanger, only one end of the tube plates at both ends is fixed to the shell, and the other end can move freely relative to the shell, which is called a floating head. The floating head is composed of a floating tube plate, a hook ring and a floating head end cover, and is detachable connection, and the tube bundle can be drawn out from the shell. The thermal deformation of the tube bundle and the shell are not restricted to each other, so no thermal stress is generated. Its advantage is that it is easy to clean between and inside the tube without thermal stress; but its structure is complex, the cost is higher than that of a fixed tube-sheet heat exchanger, the equipment is heavy, the material consumption is large, and the small floating head end cover cannot be checked during operation. The sealing requirements are higher during manufacturing. It is suitable for occasions where the wall temperature difference between the shell and the tube bundle is large or the shell side medium is easy to scale.

Heat exchange reactors are also called non-adiabatic variable temperature reactors, and their structure is mostly similar to shell and tube heat exchangers. The catalyst can be placed in the tube or between the tubes, but the latter is less common. The gas of the heat exchange fixed-bed reactor flows down into the catalyst bed from the top of the reactor and flows out at the bottom. In actual production, most of them use a top-down flow method.

Before entering the formal reaction, a preheating heat exchanger is used to preheat the reaction materials to a suitable temperature in advance. This type of heat exchanger is called a preheating heat exchanger. The commonly used structure is a shell and tube heat exchanger.

This kind of heat exchanger is to bend the metal tube into various shapes suitable for the container and immerse it in the liquid in the container. The advantage of the coil heat exchanger is that it has a simple structure, can withstand high pressure, and can be made of corrosion-resistant materials; The disadvantage is that the liquid turbulence in the container is low, and the heat transfer coefficient outside the tube is small, in order to improve the heat transfer coefficient.